In early 2021 I was contacted by Arne Rohde who had found me via LinkedIn.

We had been colleagues at BeoCenter 7000 where Kai Rostrup Jensen was project manager, and BeoCenter7700 where Mogens Habersaat was project manager.

In the time after these projects we had a little chat when we met in the hallway, and later when Arne moved to New Zealand, when he checked in on us old colleagues in PU (product development). But it was getting to be a long time since the last time.

Arne told me about his “writings” and sent a link to it.

And I must say it has been extremely interesting reading, including the appendices. It brought back good memories that had otherwise been forgotten.

We wrote a bit back and forth, triggering each other’s memories to bring out a bit more detail, it was fun.

I mentioned some things that weren’t in either his text or the appendices, and when he asked if I’d like to do a post of my own, I immediately said yes-thank you. That’s what you’re reading now!

I’ve tried to be true to the subject, but I’ll also give some background on my own role in the subject. You’ll have to bear with that, possibly skip it 😊

My background:

I was hired in 1973 by Erik Bækgaard as a designer in the radio department under Jørgen Nielsen, and with Ole Gade Pejstrup as my project manager. Others on the HW team were Tom Jelsing (FM) and Eli Tonsberg (AM). BeoMaster 2000 and BeoMaster 3400 (4 -channel stereo) were about to go into production, but the person who had designed the LF (low frequency) and output amplifier had resigned. That was my luck as I had an unsolicited application lying around which was activated.

The output amplifiers in these BeoMaster radios were the first B&O versions with DC coupled output and they were very proud of them. Right up until the Finn, as Tom describes, took the finishing touches off them. The amps suffered from TIM (Transient Intermodulation Distortion) which basically meant they were best at playing only one note at a time. They were, however, better than those in the BeoLab 5000 given to King Frederik in 1967, and on a par with most other amplifiers on the market.

But that was a time without any kind of μP (microprocessor) and digital stuff. So the trade journals around the world focused on transistor sound. And it was a bucket of cold water to say the least for B&O, which was all about good reviews.

Tom came up with a TIM free concept and implemented it in the BeoMaster 4400, and I was tasked with adapting the design as quickly as possible and getting it implemented in the BeoMaster 2000 and 3400. It was something of a baptism of fire for a green-from-school young man, but with support from Tom and Egon Bjerre it could only succeed. But Pejstrup often came, with his mouth agape, and asked: well, how’s it going?

The first project I participated in from the start was BC7000. The HW team with Egon Bjerre as coordinator and responsible for μP , Jørgen Selmer on the tape recorder part, Claus Dissing on FM and yours truly on amplifiers and power supply. And Erik Bækgaard as supervisor on Tolra. It was a great apprenticeship for me.

The bustle around programming I remember most as active traffic at Kai Rostrup’s desk, and that Egon when he arrived in the morning immediately disappeared into the private room with various tapes and ring binders. And that Arne came on the scene and solved all SW problems.

BC7000 was upgraded to BC7700 where I got the coordinator role and responsibility for μP. Mostek 3870 was chosen, experience from BM6000 showed that it emitted less noise, probably because it had internal PROM. Then Arne had to deal with the not so advanced instruction set. The BC7700 was upgraded to a two-way IR/remote system, and Poul Nielsen was in charge of the 2-way user control panel. These were exciting tasks for both of us.

μP EMC problem in BC7000:

It came as a shock when it was found that the μP module destroyed the FM reception. Panic is probably too big a word, but for some days there were doubts about when the product could be launched, if at all.

The problem was discovered in Fab3 in “long term testing” shortly before the start of production. Here, a number of test production devices were set to run for a few thousand hours. Before that, they were re-measured for virtually all specifications. These measurements did not reveal any problem, but when an employee listened to P2 at 98.5 mHz and turned down the antenna signal, there was not as expected a little more white noise (hiss) but rather quite a lot of bird chirping.

Why had this not been detected in PU?

It had actually been thought that a μP with associated HW could cause noise and interfere with FM reception. Therefore tests had been made in the monitor room which was on the 3rd floor of the old main building. The room shielded FM reception from the outside. There the BeoCenter 7000 was tested with “rabbit ears” antenna mounted. Then the FM band was tuned through, back then it was purely manual turning through the band. No carrier waves could be detected, so the conclusion was that there was no problem.

So why was there a problem anyway?

Because the interfering signal only had to have a strength of 0.1 μvolt at the antenna input to interfere when the harmonic noise figure was at the same frequency as the desired station. And 0.1 μvolt is 20 dB below the signal that can cause even a good sensitive FM receiver to start playing poor quality mono. For stereo, at least 10 μvolt and preferably above 50 μvolt is required. So it would only require a very weak signal to interfere.

A huge effort was made by many good people to find solutions to the problem. I hope someone can contribute a photo of the solution with tinplate, and decoupling etc. It was a great bird’s nest (apropos bird’s twitter) and amazing that the Skive factory could produce it. But they did. Later, a slightly more production-friendly solution was found, but still a process that required a lot of manual work and craftsmanship. But the Skive factory could do it! And the product was a success with over 100 units produced per day for several years.

And μP noise received attention in the following projects both professionally and managerially.

At that time there were only 3 FM stations that could be received in Struer, DR P1-P2-P3. Luckily P2 was on a harmonic frequency of the μP crystal frequency, otherwise the product would have been launched with the problem. Some of us had the product at home for testing, but with such a short distance to the Mejrup transmitter we had not discovered the problem.

That it would only take a signal of 0.1 μvolt to cause unacceptable interference was not found in the BeoCenter 7000 analysis. Problem solving was too time-consuming for that. However, the BeoCenter 9000 concept work investigated whether multiple sources could operate simultaneously without interfering with each other, e.g. CD and FM. The feature was never realized in BeoCenter 9000, but I found the level in that context. Carl Henrik Jeppesen was my supervisor. I actually had the pleasure of being his HW coordinator in the BeoCenter 9000 project where he designed an FM tuner with SMD (Surface Mount Devices which are soldered directly to the PCB surface) components. B&O’s first realization with SMD. It was now only on paper I coordinated him 😊

Not so robust IR codes:

I remember so well the surprise that the IR (infrared) code format for the generation BeoCenter 7000, BeoMaster 6000, …. could be cheated.

Yet the long term testing showed its unique abilities to reveal weaknesses whatever they may be of HW – SW and mechanics. After all, there were many products under test and they were monitored both automatically and manually. And the right weather with sunshine and clouds and an appropriate amount of westerly wind combined with the skylights meant that the products were receiving OK IR codes. Not least for the volume up!

The IR architects had otherwise stated that the probability of failure would be on a par with nuclear power plant spills, and with Chernobyl and other spills this probably turned out to be close to the truth.

Trip to England:

I had a really exciting trip to England, but probably of the type where one is enough. But it was exciting for a young guy who had never been to England and experienced left-hand driving, for example.

I can’t remember if it was pick up or drop off. And whether it was Mostek or xxxx equipment. But after dialogue with Arne and reading Tom’s post I think it was the equipment for Brian (Knott) (Rockwell equipment for BM8000) that I brought to England.

They didn’t want to risk shipping it, so I ended up borrowing a Peugeot 504 estate car from Zobbe and driving to Esbjerg and boarding the ferry to Harwich. After 10 hours I drove ashore and found Brian as agreed. I had a few hours before the ferry sailed back and Brian drove me around the countryside in his racer (Ford Capri). It made an impression just the thought of going the wrong way around the roundabouts. Then back on the ferry and 10 hours sailing and back to Struer. It was a very good trip, but one was enough.

New mask BC7700:

We did a mask revision for Mostek 3870 4K in BeoCenter 7700. I can’t remember why, and neither can Arne. I think I remember it because I had the opportunity to revise some choices regarding the i/o configuration. The individual pins could be configured for pull-up, or pull-down or open collector.

It was very uncommon to do mask revision because it was expensive and it took a long time from sending programs and to receiving Prom versions.

Can’t get any closer than that there might have been a difference between the eProm piggyback and Prom versions that caused problems.

Fortunately for me.

μP courses and what they initiated for example:

Shortly after Arne was hired to rake the chestnuts out of the fire regarding Texas μP and saved several projects, he held some internal μP courses for us HW geeks. The courses were held outside working hours, but at that time we didn’t care much about inside and outside. The courses were much appreciated and we learned about machine language – assembler etc. How to sample keyboards and deal with key bounce, how a SW clock routine based on mains frequency finds out if it is 50 or 60 Hz etc etc.

The courses were even very useful later in the projects when HW people could talk about SW in a meaningful way.

Privately there were also some who benefited from these courses for private projects.

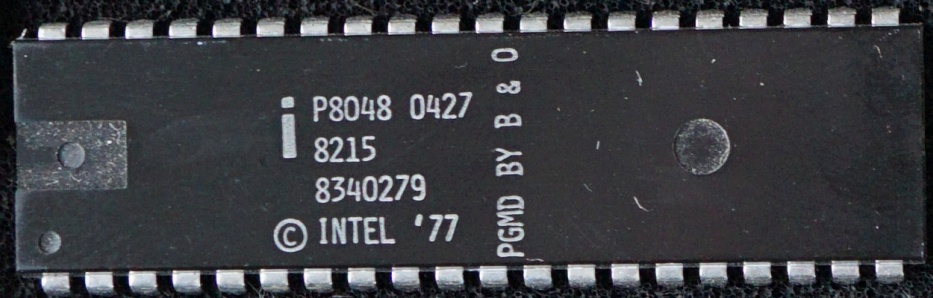

I constructed a development system to program the Mostek 3870 in machine code. Poul Nielsen, who was responsible for the 2-way panel in the BC7700, helped with the concept of static RAM 6116. Via the equipment the 6116 could then be accessed from the 3870 during program run, and from various digital HW programming wise.

See picture. I found it in a box where the equipment was filed in 1989!

The addresses (buttons/switches on the left) could be set in step or run, up and down. Or reset to 0000. Machine code bytes could be set per nibble, and loaded into static RAM via the red button.

Modes (buttons/switches on the right) could be set for programming, program run etc.

All 4 ports could be accessed via the 4 Molex connectors, so various HW could be connected (keyboards – displays – A/D and D/A converters, digital potmeters, etc. Etc.

Once the program was finished, the IC socket mounted in the PiggyBack socket of the 3870 could be moved into an eProm burner, in my case a Pecker-1

I succeeded in implementing equipment for running competitions in model boats, cars and airplanes.

Also a 7 channel encoder for a 35MHz FM transmitter, which allowed quick switching between different setups of trim for models, depending on wind and weather.

All initiated by an interest in programming triggered by project work with the first B&O products Arne programmed as well as his internal courses in programming for us HW guys.