Regarding my remarks, it is my personal opinion that you could well mention the “resistance” there was in the early days to the introduction of the microprocessor in our products.

It was the very market oriented managers who fought against it. Jens Bang was one of them. He was very market oriented (despite his engineering education) in his otherwise very capable work as a product planner. He was afraid that in technical “enthusiasm” it would get out of hand, and that it would be too expensive for the product price. The component price was a known factor.

Whereas I, as the technical person responsible, in an early discussion with Erik Bækgård and Tom Jelsing, for example, saw with them a lot of new possibilities for new types of functions and operating techniques in our product ideas, which you yourself were very much involved in discussing and finding. These were possibilities that I didn’t think we should ignore.

At that time, I was “interrogated” by the product committee, i.e. the board of directors, which was responsible for the decision to start the flow of expenditure that was a development product. Fortunately, they believed me.

I think it should perhaps be mentioned briefly, since it is after all part of the history of the product development that took place through the technological development (not just at B&O) and where the microprocessor was in my opinion the start of the total digitalisation that changed many technical methods completely, and where those who did not dare to follow were punished, perhaps even with company demise.

Extract from page 147 to 151 of the book Bang & Olufsen 1960 – 1990 published by Hovedland. This section written by Bent Møller Pedersen, scanned and converted by OCR and translated with the help of DeepL.com

HX-Pro

The HX-Pro is a fun little milestone in B&O’s technical evolution. When you want to record music on a tape recorder, you have to magnetise the tape. This is done using a high-frequency tone called the bias signal. In the case of powerful recordings of music, where there was a high content of very high tones, slight distortions could occur. One of B&O’s experienced tape recorder designers, Selmer Jensen, set out to investigate this type of distortion thoroughly. In short, he found that high levels of very high notes in music could cause distortion because they mixed with the high frequency tone of the bias signal. He created a circuit that analysed how much high frequency content there was in the recorded music and, based on this, adjusted the bias signal downwards so that no distortion occurred. Selmer incorporated the principle into Bang & Olufsen’s tape recorders and was pleased to have got the distortion under control. So it was colleagues who had to tap him on the shoulder and point out that he had indeed made a unique discovery. B&O patented the principle and an American company, Dolby Labs, was interested in marketing it alongside their Dolby noise reduction systems. Dolby Labs was granted the right to market in return for a licence from B&O, and the system was then given its name: HX-Pro.

Introduction of microprocessors

Transistors are also called semiconductor devices. In the 1970s and 1980s, semiconductor technology developed explosively. Computers made of transistors had long been known, but now semiconductor manufacturers began to be able to fit thousands of transistors into one component, a so-called integrated circuit, and what are now called computer chips.

In the early versions, it was only possible to fit a few thousand transistors, but this made it possible to have a computer function in one component, a computer function that could be controlled by its own small on-board program. The computer program you put into it gave the component its properties. The first components were quite expensive, the cheapest about US$10 each.

So there was some scepticism when I presented the new possibilities to the ideas group and the board. The products should not be prejudiced by technical ambitions. This was a valid point of view, but the electronic technical manager, the digital engineers and, not least, myself, mobilised a certain amount of stubbornness because we were convinced of the new ideas that were waiting to be exploited. A microprocessor was colloquially called a micro-P., and for reasons of rationalisation I was colloquially called Møller P. My constant pleas for microprocessors therefore earned me the nickname Møller-micro-P. in certain circles. The baptism was performed in the idea group by Jens Bang. But it didn’t take many demonstrations of the possibilities before everyone agreed that we were getting value for money.

The most obvious advantages of using microprocessors were that you could have multiple functions on one button and user programming that could, for example, make time-programmed tape recordings. The first product where we used microprocessors was the Beocenter 7000 – the microprocessor used was from the company Rockwell, and the technical characteristics and price were optimal. Almost at the same time we had started the development of a top of the range Hi-Fi system called the Beolab 8000 system. Here our functional ambitions were greater, and with the desire to develop a linear tape counter for tape recordings, we found a processor with built-in multiplication and division instructions from the American company Texas Instruments.

The focus on this frontrunner in microprocessor technology has made the component type designation TMS 9940 burn itself into my consciousness. The development of the microprocessor was on a schedule such that components could be delivered four months before we needed them, and we elected to use the component. But we learned a serious lesson about risk assessment of new technology in an important project, because there were repeated delays with the component, so that in the end it was more than the project could tolerate.

I persuaded my boss, Technical Director Jens Thorsen, to come to the US to see first-hand the likelihood of on-time delivery. We talked to the project manager for TMS 9940 and he tried to convince us that the component would maintain a schedule that would not destroy our project. But his rapidly blinking eyes and twitching mouth were not convincing, and on the plane home we decided not to bet on TMS 9940 as the basis for the major development project any longer. It turned out to be a sensible decision, but it gave me many sleepless nights thinking about how things would go when part of the exciting idea base had to be removed from the project to keep it on schedule.

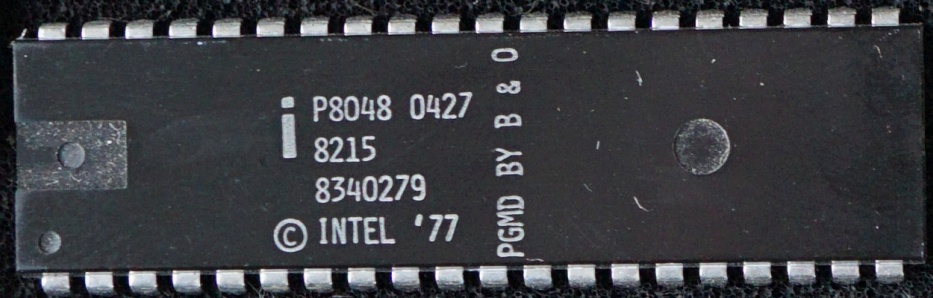

As so often before, skilled development people made the difference. Project manager Ingerslev Andersen with the project plans, technical manager Erik Bækgaard and creative digital designer Tom Jelsing put their heads together. They found that by replacing the TMS 9940 with two special processors from Intel, they could solve the problem. The two processors had to be coupled in a special way to exploit their shared memory capacity and computational structure, and could then replace the TMS 9940 without compromising the idea. The unit price was a little more expensive, but it saved the project and its idea base for launch at the right time. We all learned a lot that could be used for risk assessments when it came to introducing completely new technology in the coming years.

The microprocessor was now firmly established as part of B&O’s operating concept. In the Beosystem 7700, where the link system was introduced, the new logic options meant, for example, that a link system only opened up the sound in the loudspeaker room where the terminal was used. And also that the status of the product in the main room could be shown on small displays at the speakers in the side room. The next product step in the microprocessor’s triumphal march was the Beosystem 5000. This consisted of four individual products – a tuner-amplifier, a tape-recorder, a CD-player and a gramophone – operated from a single control panel which could be placed anywhere in the living room. The discreet and beautiful design of the individual products by Jacob Jensen made the system a B&O classic. Microprocessor technology was used with a processor both in the control panel and in each product, so that they could, popularly speaking, talk to each other. The infrared light that transmitted the control codes was extended to also be a system that sent messages back to the control panel. In this way, operating security was increased by means of a so-called handshake procedure, but also convenience was increased, because displays in the control panel constantly showed what was happening in the individual products. Time programming was extended so that the system could be programmed to do different things for each day of the week, such as being woken up to music in the morning. Another product feature of the public address system was that the way the microprocessors of the individual products talked to each other meant that if you switched off the system at the touch of a button, the microprocessors made sure that the system was cleaned up before it was switched off, i.e. all products were stopped, the tone arms of the gramophones were put back in place and drawers in CD players, for example, were closed before the lights went out in the system.

Then it became routine to use the microprocessor in B&O’s products, such as in the Beocenter 9000, where doors had to be opened and closed, and where the centre became the core of an audio/video link system.

(Numerous conversion and translation errors have been corrected, but it’s not inconceivable that some are still buried in the document.)

Next chapter: Appendix 6: Contributed by Else Skovdal